Product Sub-Menu

Industrial Remote Control

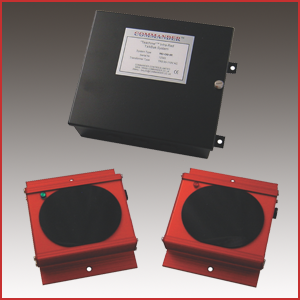

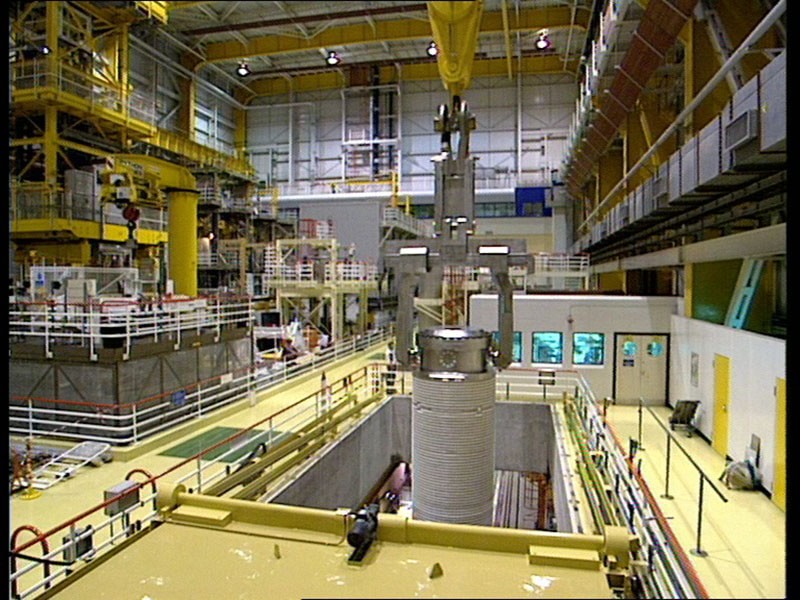

The XBData™ Bridge to Hoist(s) Command & Communication System provides a safe, economical and cost effective way to eliminate cross bridge control & power wiring on the bridge & festoon systems. Old method systems are commonly associated with costly downtime when such systems fail by way of mechanical collapse or simply wear out at end of life and their hanging loops can also fail through constant flexing or get snagged & ripped out on loads or caught up in high ‘in factory’ machinery or other obstructions either permanent or temporary. Instances have occurred when unequal festoon loops (hanging low) have snagged on and toppled structures being worked on resulting in injuries to workers. The XBData™ system can be used on cranes with single or multiple hoists each with their own ‘on board’ motor control panel. The XBData™ system is in addition to the usual COMMANDER™ remote control system (Infra-Red or Radio), each hoist would require a single receiver decoder, sized to suit the number of output commands for each hoists’ functions. Cross bridge transmitted data would be addressed to each crab/trolley/hoist. The 415V AC power supply for the crab/trolley/hoist can easily be installed along the crane bridge (see picture on the brochure) using enclosed conductor bar, common to all on bridge lifting systems, the supply wired from the load side of the crane MLC thus ensuring Category 3 safety is maintained. Collectors are installed on each crab/trolly/hoist similar to those on crane gantries to provide a power source to the crane bridge. As well as facilitating in works testing of new cranes, in the event of hoist removal from the crane bridge or even during erection of the crane and hoist(s) on site connectivity or motor polarisation (direction) issues should be eliminated.